-40%

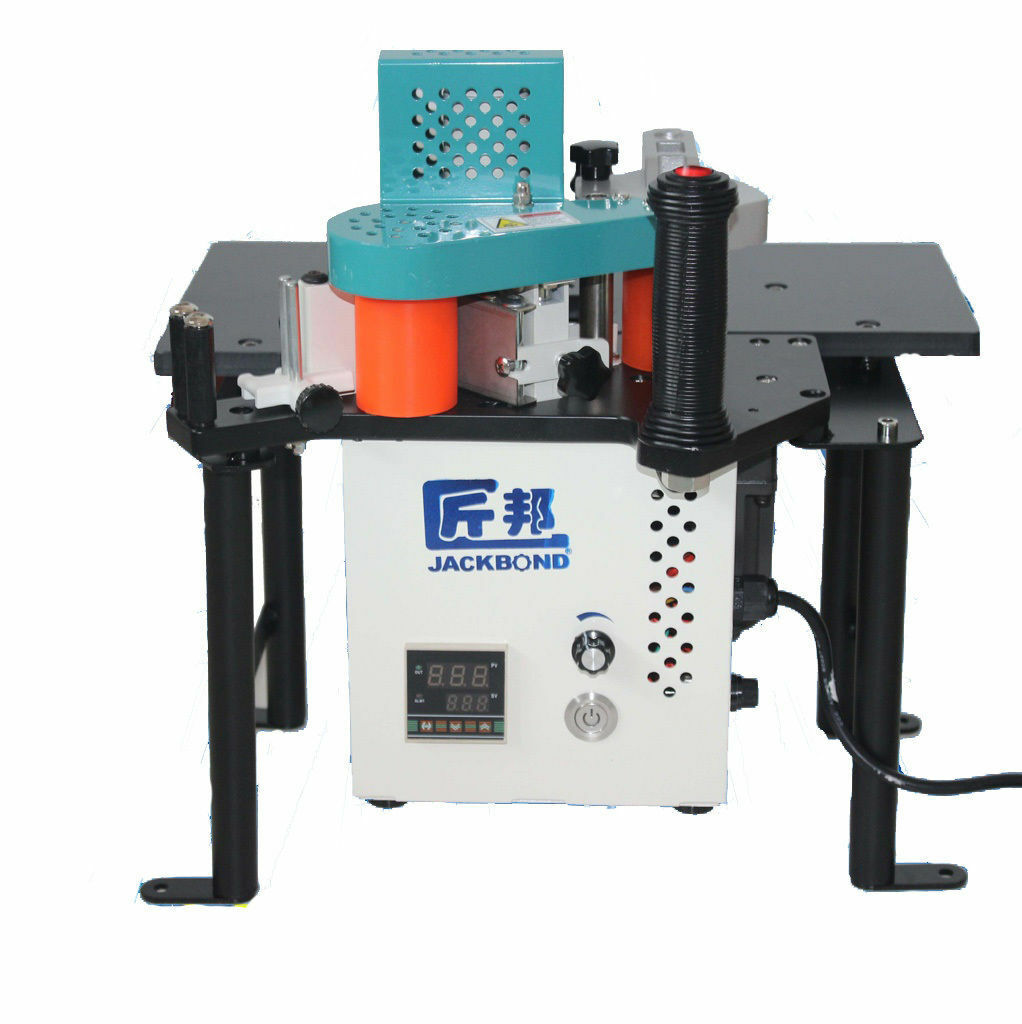

IMA ADVANTAGE 500 L Edgebander with Pre-Milling and Corner Rounding

$ 21067.2

- Description

- Size Guide

Description

IMA ADVANTAGE 500 L Edgebander with Pre-Milling and Corner RoundingBasic Specifications

:

Edgebanding capacity: Coiled material 0.3 - 3 mm (0.012 - 0.118"); strips 3.0 - 12.0 mm (0.118 - 0.472); panel thickness min/max. 8 - 60 mm (0.315 - 2.362").

Equipped With

:

Pre-Milling Unit

08.379

with: 4 kW x 2 (5.3 HP x 2) 9,000 RPM vertical joining spindles, SIKO digital readouts, particle & debris air jet blower.

Glue System "EVA" (Hot Melt)

with: "Quick-Lock" System and automatic granulate glue feeding from granulate glue supply drum.

Pressure Section

with: (1) Large dia. driven and (5) idle rollers.

Workstations

:

End Trimming Unit

08.415

:

Dual motor, 0.66 kW x 2 (0.88 HP x 2) suspended from the holddown beam; automatic chamfer adjustment 0° - 8°.

Rough Trimming Unit

08.055

:

Top & bottom flush trimming, W 1.0 x 2 (HP 1.34 x 2) - 12,000 RPM ea. motor; against the feed (up-milling), vertical & horizontal tracing wheels, digital readouts for adjustments.

Contour Unit

CT

U-L

:

Multi-use, top & bottom linear and vertical corner trimming, total motors (4), 2 x 180 W and 2 x 400 W, 12,000 RPM.

Profile Scraper Unit

08.519

:

Profile scrapers for up to 3 mm thick PVC banding, vertical & horizontal tracing shoes.

Glue Scraping Unit

08.521

:

Flat, top & bottom self-tracing glue scraper.

Buffing Unit

08.617-2

:

Top & bottom 0.18 kW x 4 (0.25 HP x 4) - 1,400 RPM.

Edge Smoothing Unit:

Top & bottom for 1, 2 and 3 mm edge

Complete With:

Control System

ICOS OPEN TS,

large color LCD display; displays stored data, on/off work station sequence, troubleshooting diagnostic; data input by touch screen, alphanumeric keyboard, and mouse. Microprocessor adjusts according to stored programs or input; pressure section position & pressure control, vertical positioning of all hold-down beam mounted workstations.

Heavy Duty "sliding" feed chain

with 70 mm wide x 60 mm long rubber pad inserts, central lubrication of transport chain, variable feed speed 4 - 20 MPM (13 - 65 FPM);

Motorized central height adjustment

of top pressure beam with double V-belt hold-down.

Sound enclosure

, all stations, all trimming & milling motors DC electrical motor brakes for immediate stopping.

Spraying Units,

upfront at in-feed for anti stick solvent and polishing solvent prior to Buffing Station.